For some time now, the occupational risk prevention has long been a chapter inherent to the company’s own business activity. Over the past few decades, organizations have taken very seriously the occupational health and safety.

The reasons for this consideration of occupational safety safety at work are several. First of all, because this prevention policy drastically reduces the accident rate of the workforce and, with it, the level of absenteeism due to sick leave. Secondly, because a working conditions increase the well-being of all professionals and, with it, their degree of satisfaction and loyalty to the company. and, with it, their degree of satisfaction and loyalty to the company; in other words: stimulates higher productivity.

However, after years of policies of occupational risk prevention policies in companies, is there anything more that can be done in favor of workplace safety? safety at work? The answer is yes, and it involves the digitalization of the management of occupational risks.

Advantages of the digitalization of occupational risk prevention

In the digitalization process companies have already begun, perhaps the occupational health and safety occupational risk prevention is one of the latest. Its managers have not yet embraced this transformation. However, the advantages of doing so are equally decisive for the future of the organization:

- Increased efficiency in management of occupational risks.

- Prevention of imminent dangers to the integrity of the templates.

- Real-time data analysis for better forecasting.

- Time and cost savings in the preparation and execution of security plans.

In short, the digital solutions for the prevention of occupational risks achieve three objectives of any company: to reduce the margin of error as much as possible, to act more quickly in the event of unforeseen events, to analyze historical security data in order to develop specific and customized solutions. And all this in order to achieve a accident rate that tends to zero.

.

How to digitize safety at work

The SAP solutions are, once again, the simplest and most effective response in the process of digitalization of a working environment and, especially, industrial. SAP allows gaining job security through applications that use from augmented reality to ergonomic risk monitoring or response to potential emissions.

Thus, i3s has developed LEKUnet, an online tool perfectly integrable in the SAP ecosystem SAP ECOSYSTEM ecosystem (but also outside of it) for those organizations that want to improve the occupational risk management and increase the safety of their work teams, especially in complicated or particularly sensitive economic activities.

LEKUnet Risk Prevention incorporates AI and geolocation technology to create safe and controlled work environments through continuous evaluation. In fact, this SAP solution solution for safety at work is capable of monitoring the location and mobility of people and materials, in order to increase control over the control over risks and reduce and reduce accidents.

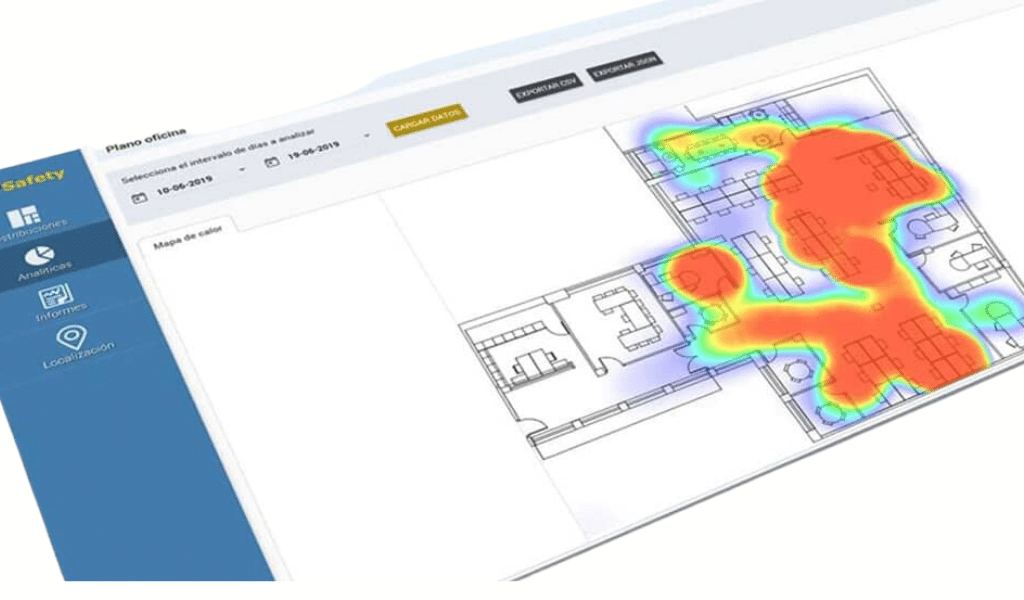

How? LEKUnet develops an exact replica of the physical workspace in a digital environment. In this, we can carry out comprehensive monitoring of the movement of people and materials for greater control for greater control to avoid accidents and, in case they happen, to be able to offer an immediate response.

Towards maximum safety and health at work

According to the the latest accident rate data provided by the National Institute for Safety and Health at Work (INEHSA), the In the last twelve months, the incidence rate has increased by 7% (11.2% in the services sector). So did the variation in the incidence of fatalities, which increased by 20 % (104 % in the agricultural sector). With these data in hand, much can be said in favor of digitization to ensure the maximum occupational health and safetyespecially in production, processing, treatment and storage activities.

And the fact is that the Annual Report of Accidents in Spain in 2021 indicates that these jobs or tasks are the ones that accumulate, in our country, the highest number of accidents (33.4%). This is followed by auxiliary activities (with 21.8%) of installation, repair, maintenance, cleaning, reception of raw materials, etc.

In this sense, the emergence of technologies such as AI or Big Data and digital platforms or tools designed for work environments represent a great opportunity not only for companies, but also for the workforces, which see their security measures increased. Applications such as LEKUnetintegrated in SAP environmentsThe new, fully flexible, scalable and customizable software allows you to automate basic tasks in the prevention of occupational hazardsFor example, classifying jobs within the company according to the risk they entail in order to develop specific safety plans or providing historical data that will help the company’s safety managers to identify and evaluate the risks associated with each job. security officers design truly effective protocols.